Worm Gearbox for Variable Pitch Aircraft Propellers: The Ultimate Choice for Superior Performance

The worm gearbox, a crucial component in variable pitch aircraft propellers, stands out with its unique characteristics and applications. Its unmatched operational efficiency and adaptability make it a preferred choice for a wide range of industrial applications.

Features of the Worm Gearbox

- High Torque: Worm gearboxes are known for their high torque output, which is crucial for variable pitch aircraft propellers.

- Efficiency: These gearboxes can maintain high efficiency even under heavy loads.

- Durability: Built with high-quality materials, worm gearboxes are durable and have a long lifespan.

- Compact Design: Despite their high power output, worm gearboxes have a compact design, making them suitable for space-constrained applications.

- Noise Reduction: Worm gearboxes operate quietly, reducing noise pollution in the workplace.

Why Worm Gearboxes are Ideal for Variable Pitch Aircraft Propellers

- Precision: Worm gearboxes offer precision control, which is vital for adjusting the pitch of aircraft propellers.

- High Load Capacity: They can handle the high loads that are common in the aviation industry.

- Speed Reduction: Worm gearboxes are excellent at reducing speed, providing the slow, controlled movements required for propeller adjustment.

- Smooth Operation: They ensure smooth operation, preventing jarring movements that could affect flight stability.

- Low Maintenance: Worm gearboxes require minimal maintenance, making them cost-effective in the long run.

Working Principle of a Worm Gear Motor

The worm gear motor operates by having a worm (a gear in the form of a screw) mesh with a worm gear. The rotational movement of the worm causes the worm gear to rotate, which in turn drives the output shaft. This process allows for significant speed reduction and an increase in torque.

How to Select the Right Worm Gear Reducer

- Load Requirements: Consider the load requirements of your application.

- Speed: The speed requirements of your application will dictate the type of worm gear reducer you need.

- Size Constraints: The available space in your application can influence the size of the reducer you choose.

- Environment: The operating environment can affect the durability and lifespan of the reducer.

- Cost: The cost of the reducer should align with your budget.

Motors for Worm Gear Reducers

Motors and worm gear reducers work hand in hand to deliver optimal performance. The synergy between these two components is crucial in achieving the desired output. We also offer electric motors specifically designed to work with our worm gear reducers.

electric motors for Worm Gear Reducers”>

electric motors for Worm Gear Reducers”>

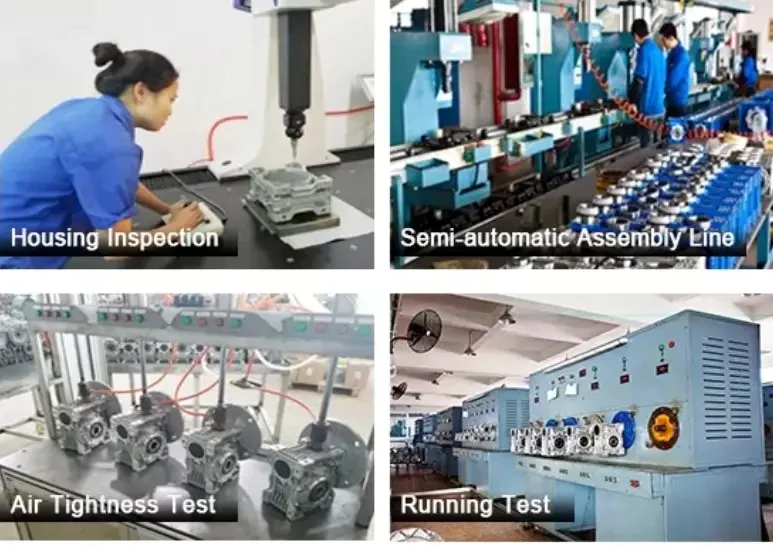

Choose Xinlan for Superior Worm Gearboxes

At Xinlan, we are committed to providing top-notch worm gearboxes that meet and exceed industry standards. With over 15 years of experience, we have made a name for ourselves in the industry, serving clients across Europe, America, Africa, and Asia. We offer the best services, high-quality products, and competitive prices. Explore our product range and contact us for your purchase now.

Frequently Asked Questions

Q1. What makes worm gearboxes suitable for variable pitch aircraft propellers?

Worm gearboxes offer precision control, high load capacity, speed reduction, smooth operation, and low maintenance, making them ideal for variable pitch aircraft propellers.

Q2. How does a worm gear motor work?

The worm gear motor operates by having a worm mesh with a worm gear. The rotational movement of the worm causes the worm gear to rotate, driving the output shaft.

Q3. What should be considered when selecting a worm gear reducer?

When selecting a worm gear reducer, consider the load requirements, speed, size constraints, operating environment, and cost.

Edited by Zqq.